Overview

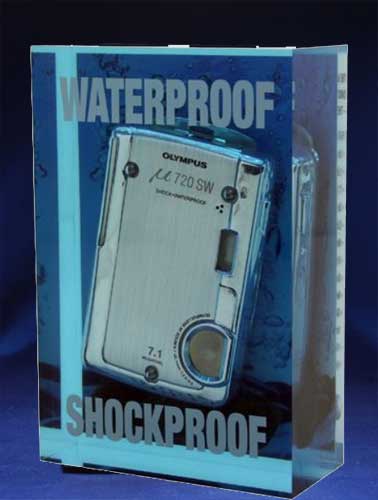

Acrylic resin embedments, often called acrylic embedments, Lucite embedments, or acrylic encapsulations, are premium display pieces created by embedding objects or printed materials into solid, crystal-clear acrylic. They provide a permanent, glass-like presentation that’s durable, UV-stable, and highly customisable in shape, size, and content. Embedments are used for financial tombstones, memorabilia encasements, product promotions, pharmaceutical and medical gifts, Point of sale and Awards.

Applications

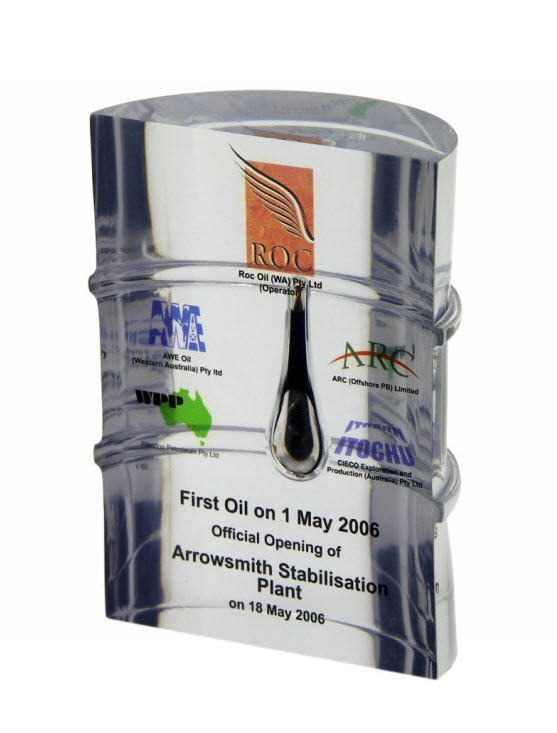

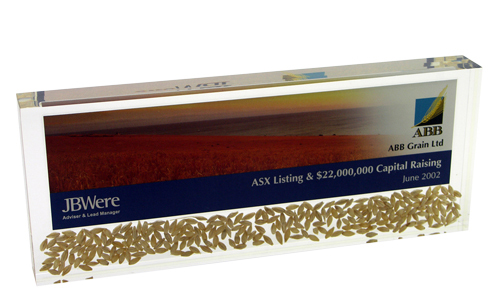

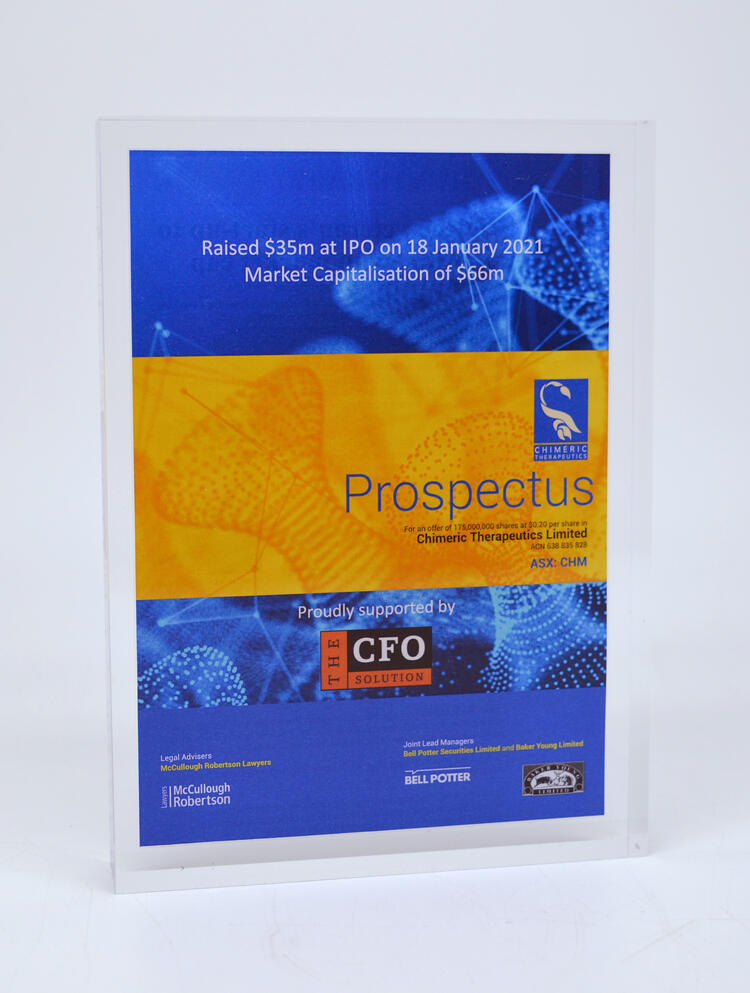

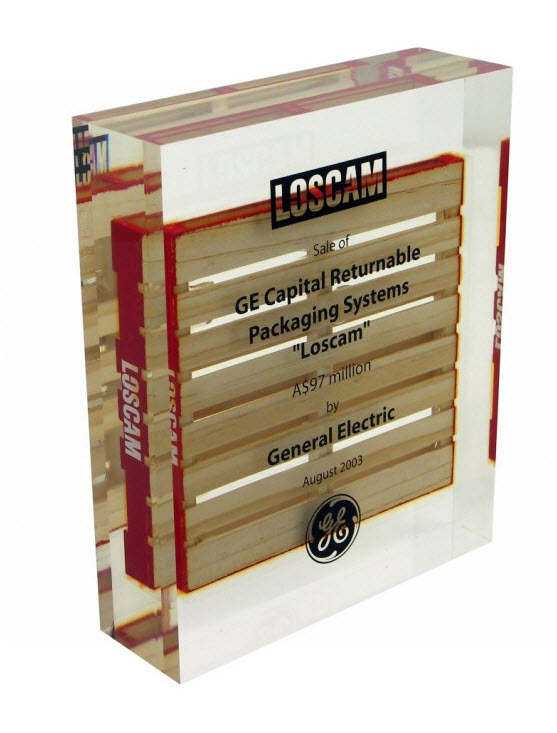

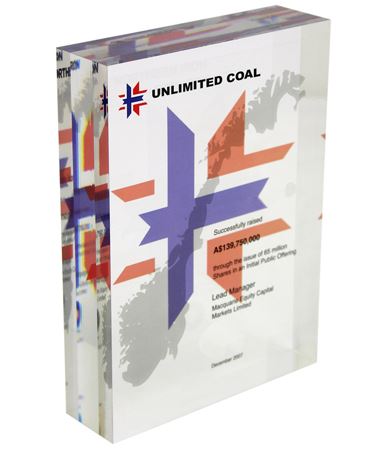

1. Financial Deal Toys / Tombstones

Commonly used by banks, law firms, and advisory groups to commemorate major financial transactions, mergers, and acquisitions. The embedded elements (such as printed deal details, logos, or even physical components like stock certificates or coins) are preserved inside crystal-clear acrylic, creating a prestigious and lasting keepsake.

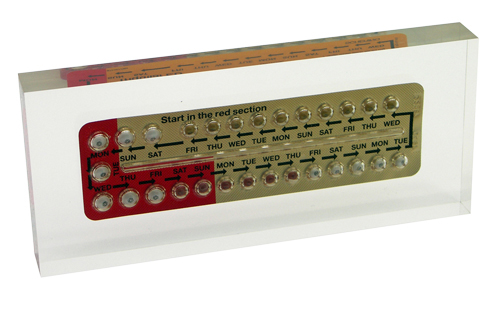

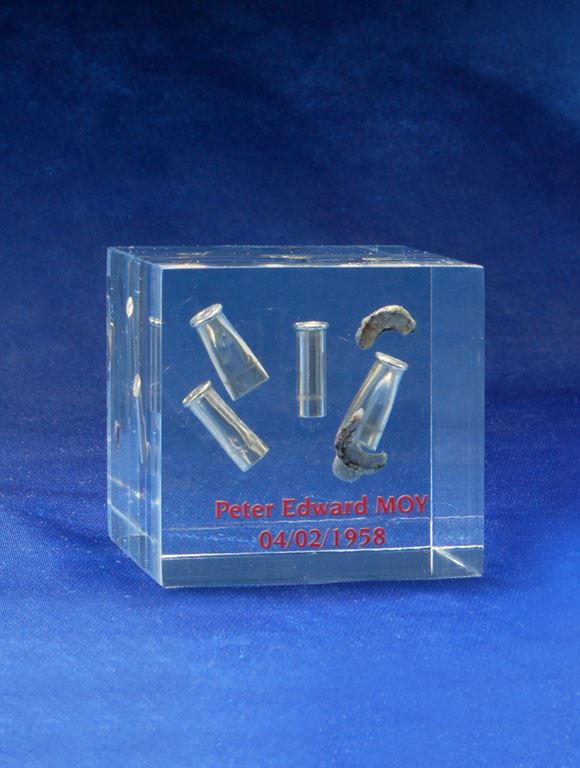

2. Memorabilia Encasement

Used to permanently display and protect small items of sentimental or historical value — for example, medals, coins, tickets, or product samples. The encapsulation process seals the item completely within the acrylic, protecting it from dust, moisture, and handling damage.

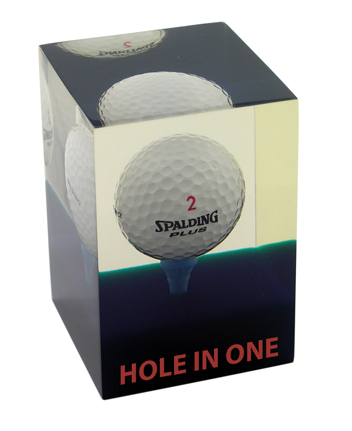

3. Custom Awards & Trophies

Acrylic embedments are also used to create unique trophies where 3D objects, text, or images appear “suspended” within the block. Perfect for corporate awards, commemorative gifts, or creative promotional pieces.

Manufacturing Process

The process involves:

Casting in Layers: Clear liquid acrylic resin is poured in multiple layers around the object or printed insert. Each layer is cured before the next is added.

Embedding: The object, printed insert, or metal plaque is precisely positioned within the partially cured acrylic to achieve perfect suspension. Multiple elements can be embedded at varying depths to create a striking layered effect.

Finishing: Once fully cured, the block is cut, polished, and optionally shaped (bevelled, slanted, faceted, or contoured).

Etching or Printing: Additional engraving or UV printing can be applied to the surface for branding or personalisation.

Smashed Glass

Fragments of shattered glass have been artistically arranged across multiple layers to create this striking acrylic embedment. Each fragment is carefully positioned within semi-cured layers of clear resin, building a dynamic suspended “spray” effect that captures motion and depth. The result is a dramatic and modern memorabilia piece that transforms broken glass into a sculptural work of art.

Common Embedded Materials

Most items can be embedded, including metal, plastic, timber, grain, rock, material,

- Laminated printed inserts (deal sheets, certificates, product images)

- Metallic objects, logos or nameplates

- Coins, medallions, or miniature objects

- Sand, fabric, or symbolic artefacts

- Electronic components or branded items (for product launches)

What can't be embedded?

Not all items are suitable for acrylic embedment because the curing process generates heat and gases as the resin hardens. Some materials react to this, causing distortion, bubbles, discolouration, or damage.

- Oil-based items, such as coal (we produce replica coal to embed for you)

- Liquid that is not encapsulated in a container.

- Heat-sensitive items: wax, soft plastics, rubber, foam.

- Hazardous items: batteries, liquids, pressurised or flammable materials.

Design Options

Acrylic embedments offer exceptional design flexibility, allowing each piece to be tailored for visual impact and presentation.

Shapes and Profiles

Choose from standard blocks, wedges, domes, cylinders, or fully custom contours. Angled faces, bevelled edges, and faceted sides can be incorporated to enhance depth and light refraction.

Layering and Composition

Objects, graphics, or fragments can be embedded in multiple layers to create a three-dimensional effect or suspended appearance within the acrylic.

Colour and Finish

Clear, tinted, or frosted finishes are available. Bases can be coloured, printed, or engraved to complement your branding or theme.

Branding and Personalisation

Logos, text, or imagery can be laser-etched, sandblast-engraved, or UV-printed on the surface for added definition and contrast.