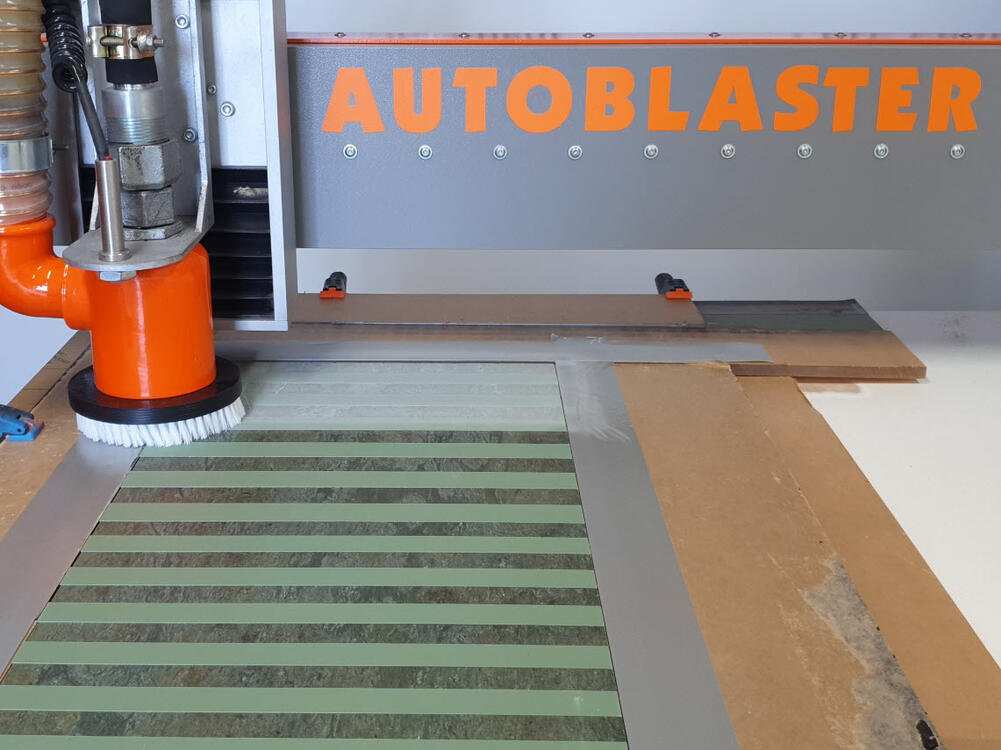

Our sandblasting services provide an effective solution for improving surface traction and helping achieve specified anti-slip ratings. Using our advanced CNC AutoBlaster, we produce consistent, textured finishes that enhance grip, essential for safety in industrial, commercial, and public environments.

This process removes contaminants and surface imperfections while creating a durable non-slip texture designed to reduce the risk of slips, trips, and falls. Whether applied to marble, aluminium, or other surfaces, our techniques improve both appearance and safety, making them ideal for floors, walkways, and high-traffic areas.

Our Process

Using abrasive media, we evenly sandblast surfaces to achieve the desired texture and finish. The result is a professional surface with improved traction, helping to create safer environments for staff, visitors, and the community.

Important Note

We do not certify or guarantee anti-slip ratings. It is the customer’s responsibility to arrange independent testing where required. However, all of our sandblasting work to date has successfully met independent slip rating tests.

We do not do on-site work. All Slip-Rating Treatments are done in our factory to pavers and tiles before they are laid.

Sandblasted Shower Tiles

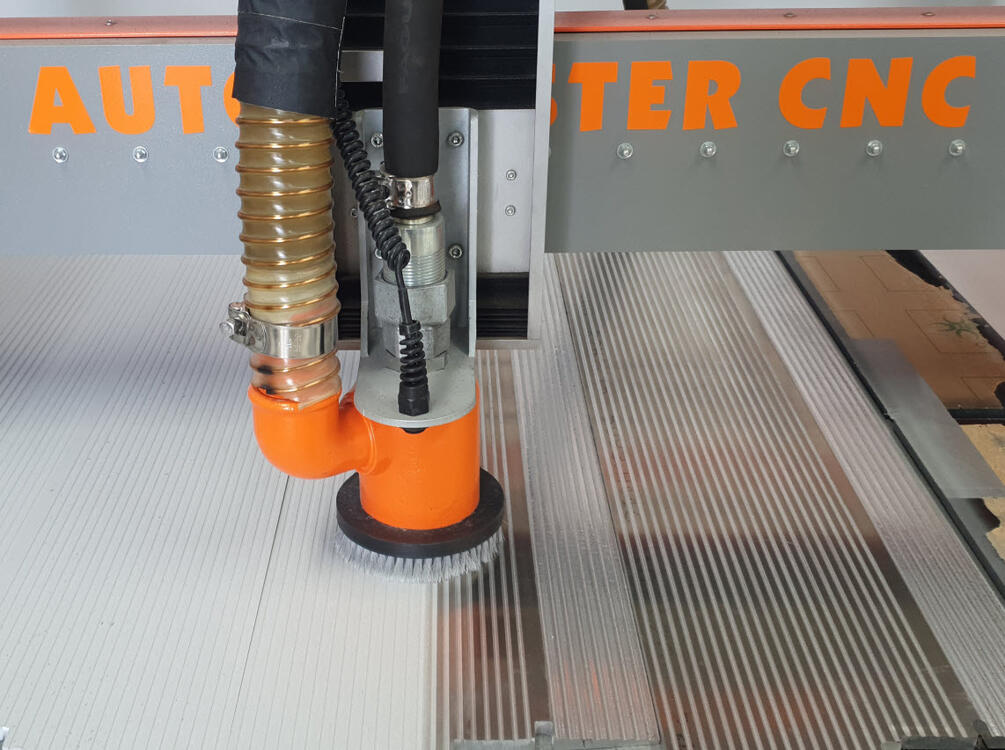

Our CNC AutoBlaster process transforms standard shower floor tiles into surfaces that combine safety with style. By engraving a precise line pattern into each tile or a whole etched surface, we enhance their anti-slip properties while creating an elegant textured finish designed for wet environments.

This method not only improves grip and reduces the risk of slips but also adds a modern, decorative detail to the bathroom floor. By sandblasting multiple tiles at once and carefully aligning the patterns, we achieve a seamless, cohesive look across the entire shower base. The result is a surface that delivers safety, functionality, and visual appeal. With the ability to customise patterns, we offer flexibility to suit individual design preferences while maintaining the highest standard of craftsmanship.

Getting your Tiles Etched

We do anti-slip processing in our factory using automated sandblasting. You provide the tiles to us on pallets, and we etch them in-house. Once etched, we re-pack them on your pallets, ready for you to arrange pick up.

Matching patterns from tile to tile can be achieved for any pattern continuity.

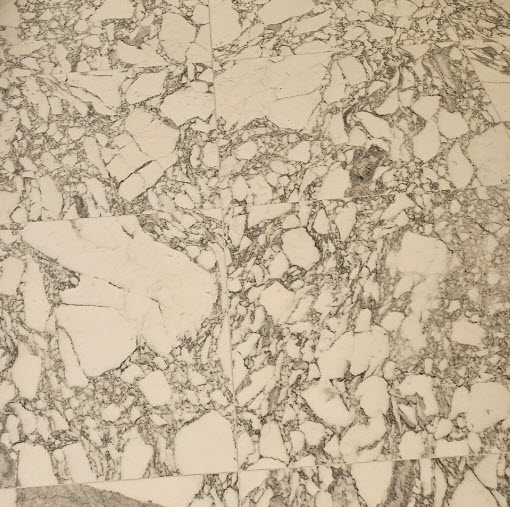

Shower & Spa Floor Tiles Project

At Barangaroo, the limestone and marble floor tiles for showers, spas, toilets, and the indoor pool underwent a specialised in-factory sandblasting treatment to address slipperiness in wet environments. They had previously been chemically treated by a specialist, but the process did not achieve the desired results. By roughening the tile surfaces with an abrasive and automated sandblasting system, this process significantly reduced the risk of slips and falls, creating a safer space for all users.

Following completion, the tiles achieved a P5 anti-slip rating under the wet pendulum test, the highest standard for slip resistance in moist areas. The enhanced traction not only improves safety but also provides peace of mind, ensuring a secure and comfortable experience for occupants and visitors alike.

We can apply our anti-slip process to various materials, including granite, marble, limestone, travertine, terrazzo, ceramic tiles, porcelain tiles, vitrified tiles, glass mosaic, and concrete.

Once the process has been completed, we recommend applying the appropriate sealant coat to protect the surface from grim..

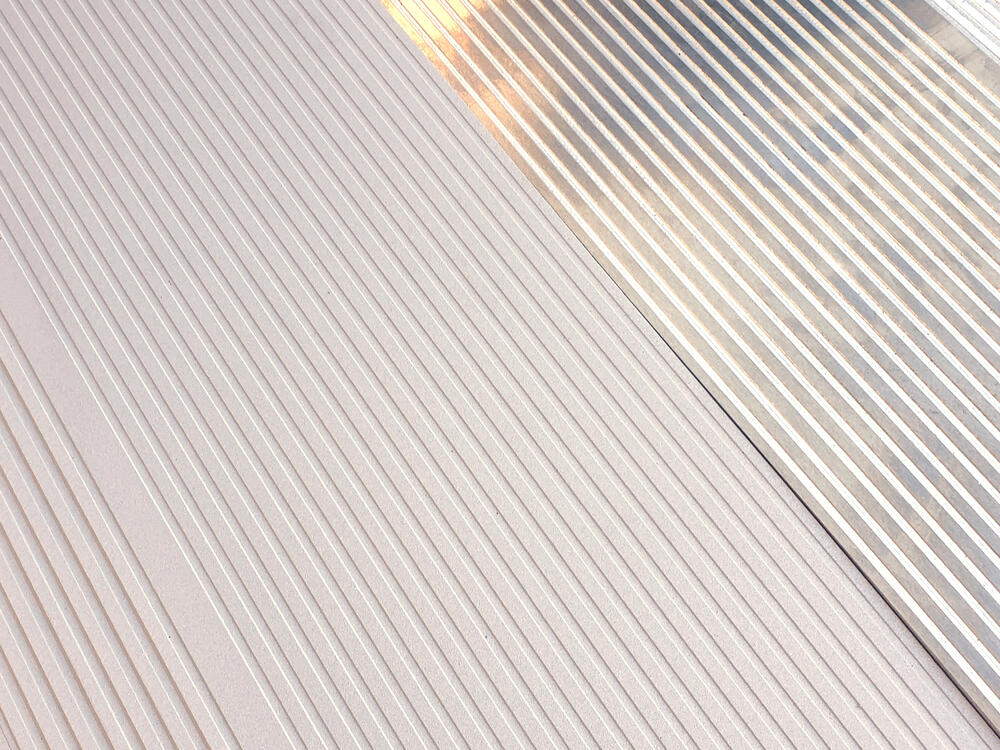

Sandblasted Aluminium Floor Panels

Utilising our CNC Autoblaster, we expertly engrave aluminium floor panels to meet rigorous safety standards. Employing precise sandblasting techniques, we enhance these panels with an anti-slip surface, crucial for environments requiring high traction.

Following thorough testing, our panels achieved a commendable P5 anti-slip rating, affirming their effectiveness in preventing slips and falls. This achievement underscores our commitment to quality and safety, ensuring our products not only meet but exceed industry standards.

The P5 anti-slip rating is a designation that signifies a high level of slip resistance for flooring materials, particularly important in environments where safety is paramount, such as industrial settings, commercial spaces, and public areas. Achieving a P5 rating involves rigorous testing to determine the coefficient of friction (COF) of the surface when wet or dry. A P5 rating indicates excellent slip resistance, significantly reducing the risk of slips and falls.

Important Note

Our sandblasting process is highly effective in improving surface traction and reducing slip risks. Independent wet pendulum testing has confirmed results up to a P5 anti-slip rating, demonstrating the strength of our approach.

However, we do not issue or certify official anti-slip ratings. For formal compliance documentation, customers should arrange testing through accredited suppliers to ensure results are aligned with their specific project requirements and standards.