What Is Stainless Steel Engraving?

Stainless steel engraving is the process of permanently marking stainless steel using techniques such as acid etching, rotary CNC engraving, sandblast etching, laser annealing, or full-colour sublimation. At Premier Awards, we offer tailored solutions to suit everything from industrial labels to high-end plaques.

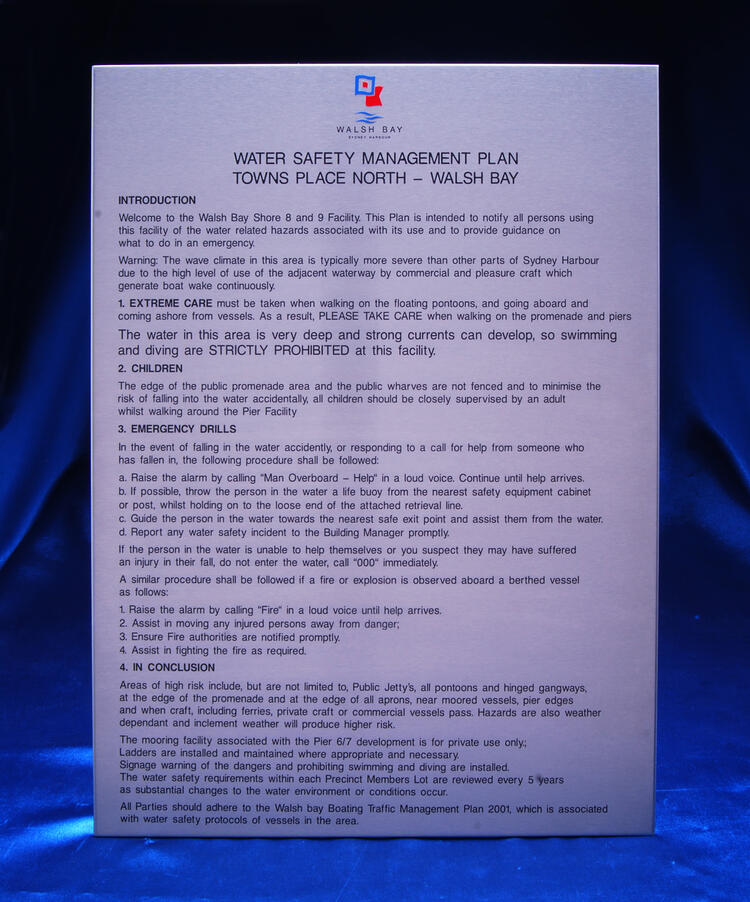

Whether it's for compliance plates, signage, plaques, or decorative items, stainless steel provides the strength and longevity you need, with a clean, professional finish. We use 316 grade brushed finish stainless steel for all work to ensure you get a marine-grade product that won’t corrode.

Why Choose Stainless Steel Engraving?

- Long-lasting and corrosion-resistant

- Modern, professional appearance

- Low-maintenance and easy to clean

- Ideal for indoor and outdoor use

- Suitable for signage, plaques, labels and more

Imprint Process Comparison

CNC Engraving

The most permanent metal engraving process. The lettering is cut into the surface by rotary engraving and then filled with paint. It is also the most expensive option.

- OUTDOOR OK

- Engraved into the surface 0.5mm

- Paint filled

- Permanent Marking 30 years plus

- $$$

Acid Etched

The most permanent metal engraving process. The lettering is cut into the surface and then filled with paint. It is also the most expensive option.

- OUTDOOR OK

- Engraved into the surface 0.3mm

- Paint filled

- Permanent Marking 30 years plus

- $$$

Sandblast Etched

A cost-effective Alternative to Acid Etching. The lettering is surface etched and then coated with paint. It delivers crisp detail and long-lasting results, making them ideal for signage, plaques, and commemorative pieces without the higher expense of traditional acid etching.

- OUTDOOR OK

- Surface etching

- paint filled

- Permanent Marking 15 years plus

- $$

Laser Anneal

A cost-effective Alternative to Acid Etching. The lettering is surface etched and then coated with paint. It delivers crisp detail and long-lasting results, making it ideal for signage, plaques, and commemorative pieces without the higher expense of traditional acid etching.

- OUTDOOR OK

- Surface etching

- paint filled

- Permanent Marking 15 years plus

- $$

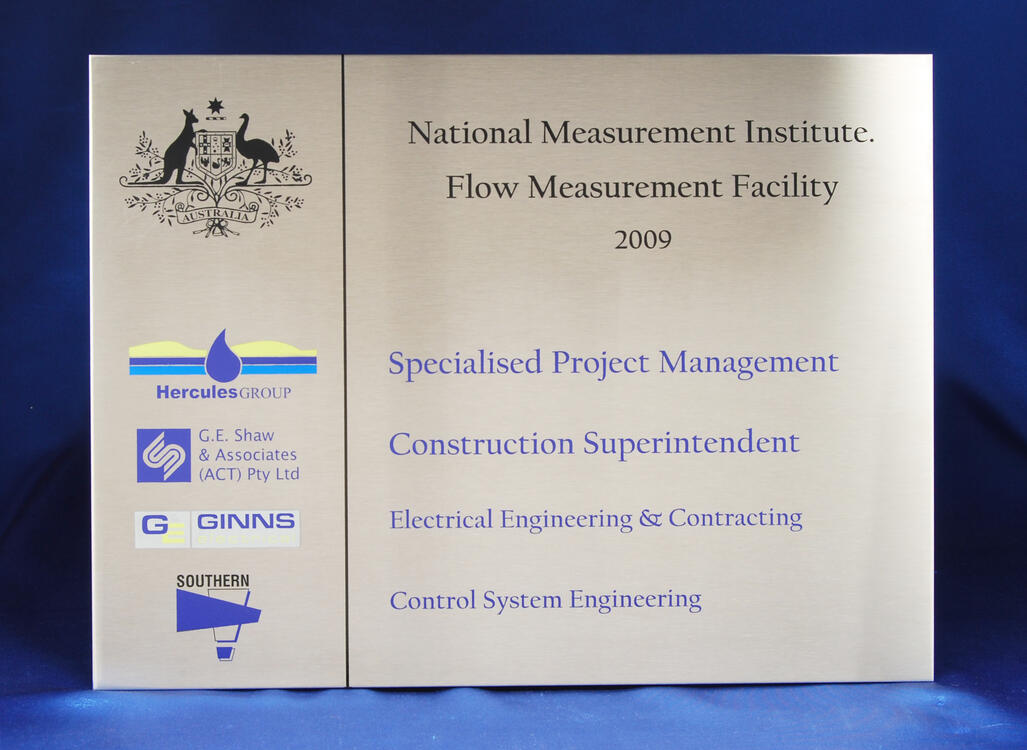

Acid Etched Stainless Steel

Acid etching is a premium process that engraves into the surface of stainless steel, creating a design or text that sits below the surface of the metal. This creates a permanent, high-quality mark that can be colour filled with two-pack epoxy paint for added contrast.

Durability: 50 Years + | Scratch Resistant | Resistant to Harsh Chemicals

Used For: Premium plaques, compliance plates and labels, architectural signs, and memorial plaques

Look: Clean, recessed engraving with paint fill

Best For: Projects needing a polished, long-lasting finish

Advantages: Excellent detail and depth of engraving, clean professional appearance

Price: $$$

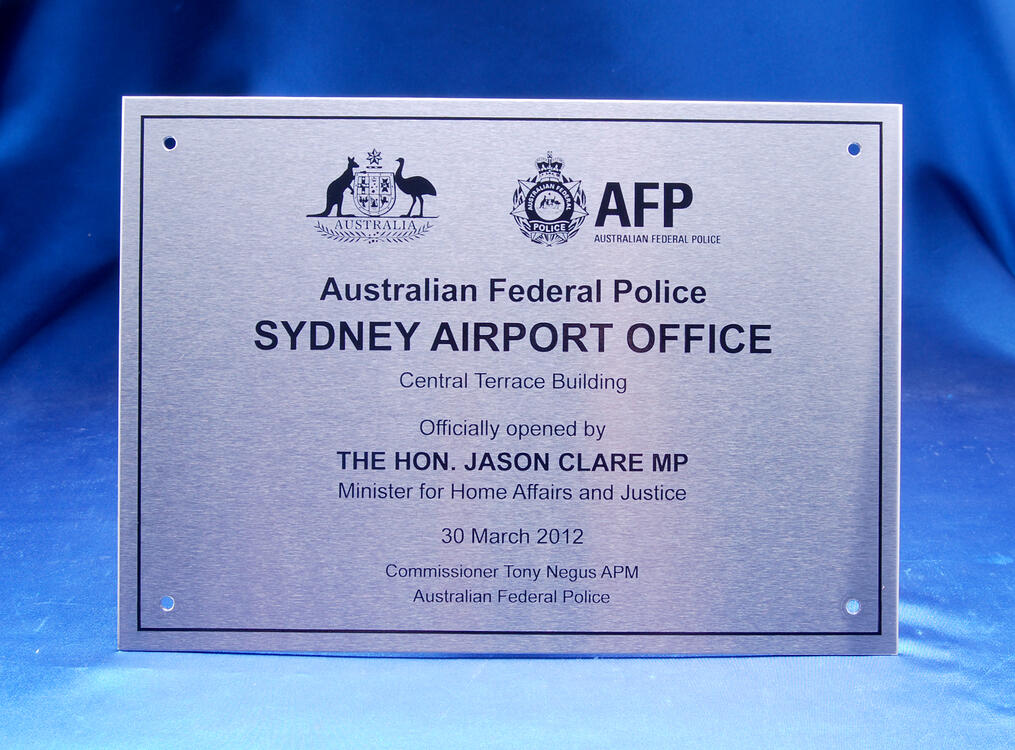

Sandblast Etched Stainless Steel

Sandblast Etching and two-pack epoxy paint fill create a permanent surface mark on stainless steel by blasting through a stencil, producing a sharp, clean etch finish with lasting durability. It’s a more economical alternative to acid etching, while still delivering a professional finish suitable for various signage and plaque applications.

Durability: 25 Years + | Scratch Resistant

Used For: Signs, plaques, labels, compliance plates

Look: Surface etch with bold paint-filled lettering

Best For: Durable, cost-effective outdoor or indoor signage

Advantages: Excellent crisp finish, and is a more economical alternative to acid etching

Price: $$

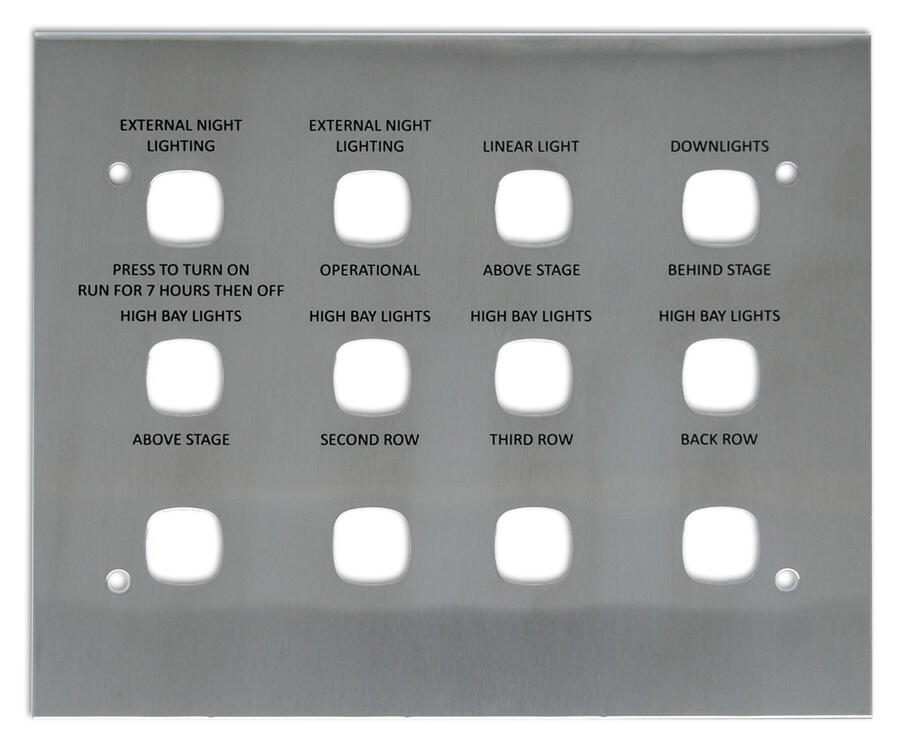

Laser Annealed Stainless Steel

Laser annealing produces a permanent black marking on stainless steel by using heat to alter the surface. No material is removed; instead, the laser changes the colour of the metal, resulting in a permanent dark, smooth finish that’s flush with the surface. This method is ideal for applications where hygiene and surface integrity matter, such as in the medical, food, or electronics industries. It’s also well-suited to industrial labels where a sleek, low-profile finish is preferred.

Durability: 50 Years + | Scratch Resistant | Excellent Chemical Resistance

Used For: Compliance plates, medical tools, asset tags

Look: Smooth black mark on unetched surface

Best For: Industrial use, hygienic environments, cleanroom settings

Advantages: Hygienic properties, economical laser marking process

Price: $$

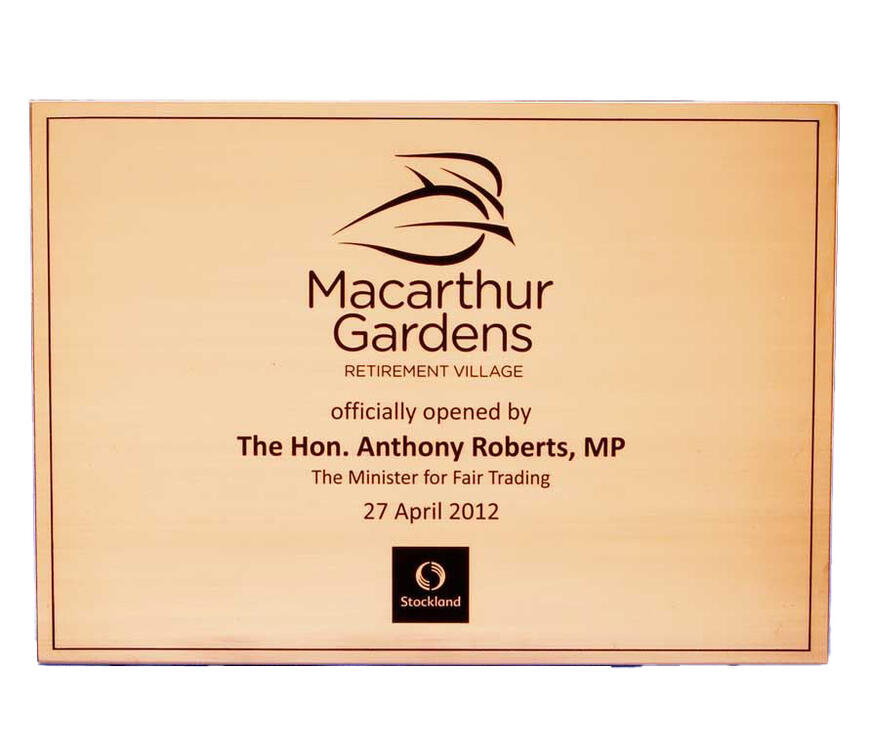

BrassTone Stainless Steel

Sandblast Etching with paint fill on gold-coloured stainless steel creates a permanent surface etching, producing crisp, detailed results. This method offers a cost-effective alternative to acid etching and traditional Brass Plaques, delivering an elegant and lasting result ideal for plaques, signage, and commemorative panels.

Durability: 15 Years + | Scratch Resistant

Used For: Signs, commemorative plaques, labels, compliance plates,

Look: Brushed gold background with crisp, black paint-filled engraving

Best For: Long-lasting applications with a prestigious finish

Price: $$

Sublimated Stainless Steel

Sublimation involves applying a sub-surface full colour printed design onto specially coated stainless steel. This process allows for photo-quality images, gradients, and vibrant colours that traditional engraving methods can’t achieve. It’s a great option for indoor signage. Not recommended for outdoor use as prolonged exposure will lead to fading.

Durability: Indoor Only | Scratch resistant | Chemical Resistant

Used For: Photo plaques, colourful indoor classy signage and labels, decorative panels

Look: Full-colour, high-resolution print on a satin stainless finish

Best For: Indoor use where colour and detail are important

Advantages: Rich, full-colour print for indoor use

Price: $

Laser Engraving Process Comparison Chart

| Method | Cost | Exposure | Durability | Time Frame |

| Acid Etch | $$$ | Outdoor | Great | 3 Weeks |

| Sand Etch | $$ | Outdoor | Great | 1-2 Weeks |

| Laser Anneal | $$ | Outdoor | Great | 1-2 Weeks |

| Sublimation | $ | Indoor | Good | 1 Week |

What we need from you:

To receive a fast and competitive quote or for order processing, please provide as much information as possible when making your enquiry.

We appreciate it when you share everything we need upfront, which enables us to hit the go button without delays; however, we understand that you may not always be able to do so. What's important to us is that if you don't have all the engraving details now, tell us when you will, so we can plan production efficiently.

Thank you for being super helpful in making the ordering process smooth.

- When do you require the order by?

- What’s your contact phone number?

- How many do you require?

- Please provide the logo and draft text

- What is your budget?

- Where do you want them shipped to?

We ask for a budget of $1 so we can find the best solution within your price range. For an idea of the cost of custom awards, you can use the price range filters or the Custom Awards categories.

Types of Stainless Steel Engraving