Trophies - Promotional Products - Industrial Engravers

- Custom

- |

-

Awards

- Primary Corporate

- Genre

- A

- B

- C

- D

- E

- F

- G

- H

- K

- |

-

Sports Trophies

- A

- B

- C

- D

- E

- F

- G

- H

- I

- L

- M

- N

- P

- R

- S

- |

-

Medals

- A

- B

- C

- D

- E

- F

- G

- H

- L

- M

- N

- P

- R

- S

- T

- V

- W

- |

-

Plaques

- Recognition Plaques

- Outdoor Plaques

- |

-

Honour Boards

- |

-

Badge & Identity

- |

-

Schools

- Academic Awards

- Popular Sports

- Badges

- Medals

- Perpetual Honour

- Ribbons

- |

-

Promo & Gift

- Promotional Merchandise

- A

-

B

- Bags

- BBQ Sets

- Beach

- Belt Buckles

- Blankets

- Bottle Openers

- C

- D

- E

- F

- H

- K

- L

- M

- P

- S

- T

- U

- Thank You

- |

-

Engrave & Sign

- Domestic Engrave & Print

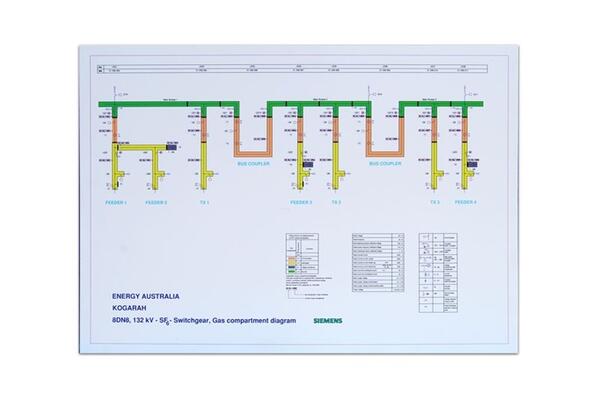

- Industrial Engrave & Print

- Industrial Labels

- Specialty Materials

- General Signage

- |

-

Misc

- Miscellanious Products

- Miscellanious Awards

- |

-

INFO

- Assurance

- You and Us

- Technical

- FAQ

- Job Opportunites

- Custom

- Awards

- Sports Trophies

- Medals

- Plaques

- Honour Boards

- Badge & Identity

- Schools

- Promo & Gift

- Engrave & Sign

- Misc

- INFO